I just finished up another client t-shirt quilt, this time from soccer jerseys. Certainly not the traditional 't-shirt', as these jerseys are polyester, requiring a bit more attention. So I thought I'd share some new hints and tips when making a t-shirt quilt.

#1: be aware of fiber content

Soccer jerseys are made from polyester, which makes them durable, stretchy, and virtually wrinkle free. Being a man-made fiber, polyester can melt under high heat. Cotton, on the other hand, loves heat!

As with any knitted fabric for a quilt, stabilization is a must! But if the fabric is polyester, it means turning down the iron heat to fuse the stabilizer. It may take a bit longer, or several passes, but it will fuse. Just be patient!

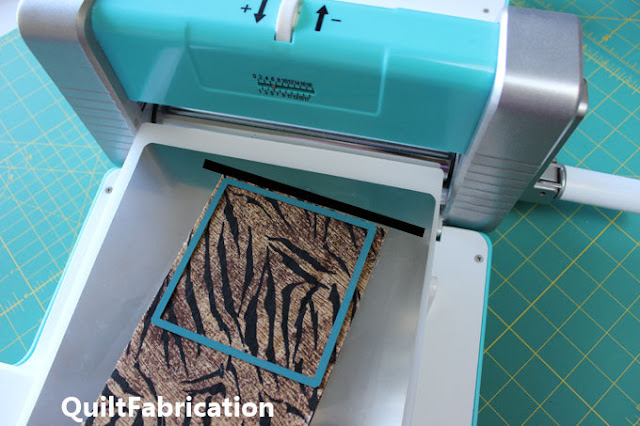

#2: use a lightweight or sheerweight fusible interfacing

Using a lightweight fusible stabilizer, such as Pellon 906F Sheerweight, is a great choice. It keeps the jersey from stretching without adding a lot of additional weight. T-shirts are already heavy enough, so no need to add more!

#3: use a teflon or silicone pressing sheet

This is super important! Applying heat to a design printed on the t-shirt can cause the design to stick to the ironing board or iron, and even peal off. To avoid that, place a teflon or silicone pressing sheet under the t-shirt, with the printed/painted side of the shirt against the pressing sheet. Then fuse away with the lightweight interfacing on top.

I've always used a teflon pressing sheet, like this one, (affiliate link)

and have discovered a new silicone version to try out (affiliate link). This one has an additional pressing sheet for the top, to make a sandwich. That's not necessary here as a damp press cloth on top of the lightweight interfacing is required for proper fusing.

Of course, these pressing sheets are not just for t-shirt quilts - they're main use is for creating a complete fusible applique, from all the parts, ready for fusing to a quilt block.

#4: it's okay to include parts of sleeves and necklines

Sleeves and necklines are usually not included in a t-shirt block. Typically, it's just the printed image on the t-shirt that's used in a quilt. But sometimes, especially if no additional sashing is used to increase the size of the quilt, it's necessary to include sleeves and necklines to bring the block up to size.

I decided to use as much of the t-shirts/jerseys as possible, cutting 15.5" x 15.5" blocks. That meant I had to use portions of the raglan sleeves and necklines. Neither was an issue, and both added interest to the blocks.

Here's the trick for dealing with the neckline opening. Before cutting the t-shirt/jersey to size, I filled the open neck area with cut-to-fit pieces (meaning with a curve or a V) from the remaining sleeves or shirt bottoms. These pieces where put into position at the neckline, with a portion extending just past the ribbing seam.

Then the lightweight fusible interfacing is applied over all.

To secure everything, a bit of stitching in the ribbing seam holds all parts together. And if desired, a bit of stitching at the top of the ribbing (original neckline opening), to hold down the neckline. Once all that's done, then the t-shirt/jersey can be cut to the block size needed.

#5: pin blocks together

When all the fusing, cutting, and designing is done, it's time to assemble the blocks into rows. With cotton t-shirts, a couple pins are all that's needed to hold things together. But polyester can be slippery, so use plenty of pins!

Also, change your needle to one that can sew knits. A ballpoint or stretch needle is a necessity to eliminate skipped stitches.

Fortunately, all the sewing machine has to deal with is the not-so-slippery stabilizer up against the feed dogs and the sewing foot. And with the right needle, plenty of pins, and the stabilizer, there should be very little slippage, and very little stretch. Row assembly becomes easy-peasy!

#6: use a lightweight cotton batting

Knits of any fiber content are thicker and heavier than quilting cotton. Add in the stabilizer, though lightweight, which contributes even more weight. Unless the goal is to have a heavy quilt to protect against freezing weather, a thin or lightweight cotton batting works beautifully in a t-shirt/jersey quilt.

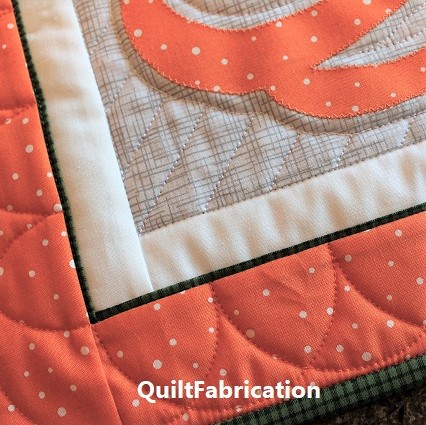

#7: use a more open quilting design

For t-shirt quilts that are made entirely of t-shirts and no other cotton fabric, a simple, open quilting design is all that's necessary. Quilt densely enough to hold the three layers together, making for a soft, love-to-snuggle-under quilt!

Happy Quilting!

Enjoyed this post? Don't miss out - get posts delivered directly to your inbox with follow.it.